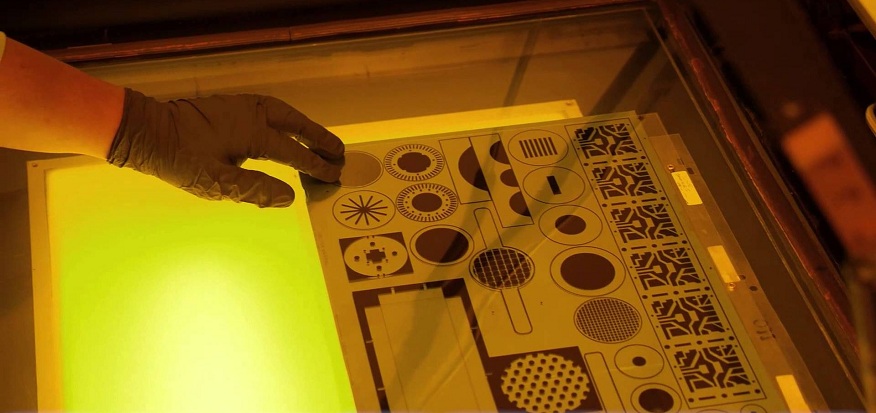

Photo Etching Process: Why It’s Important

Photo etching, often hailed as the unsung hero of precision manufacturing, unveils a world where intricate designs come to life with breathtaking accuracy and finesse. Imagine a process where creativity meets precision, where the minutest details are etched onto metal surfaces with unparalleled perfection.

Photo etching process, also known as chemical etching or photochemical machining, thrives on its ability to produce high-quality, burr-free parts with exceptional consistency while preserving the material’s structural integrity. Its non-contact, highly precise nature ensures minimal material waste, making it a sustainable choice in the world of manufacturing. From aerospace marvels to intricate medical devices, photo etching emerges as the ultimate solution for those seeking unparalleled precision, intricate designs, and efficiency in manufacturing.

The process offers several advantages across various industries, which include;

Precision and Accuracy: One of the key benefits of photo etching is its exceptional precision. It allows for the creation of intricate and complex designs with extremely fine details, often reaching tolerances as tight as a few microns. This accuracy is crucial in industries like aerospace, electronics, and medical devices, where intricate components must meet strict specifications.

Versatility in Material Selection: Photo etching is compatible with various materials, including metals like stainless steel, copper, brass, and alloys. This versatility in material choice enables the production of components with specific mechanical, electrical, or chemical properties, catering to diverse industry requirements.

Cost-Effectiveness: Compared to traditional manufacturing methods like stamping or laser cutting, photo etching can be more cost-effective for producing small to medium-sized parts in bulk. Its batch-processing capability allows for simultaneous production of multiple parts, reducing per-unit costs. Moreover, minimal tooling investment is required, making it economically viable for prototyping and low-volume production runs.

Complexity without Tool Wear: Unlike conventional machining techniques involving tool wear and potential material distortion, photo etching is a non-contact process. This means that the chemical etching method doesn’t impose stress, heat, or mechanical force on the material, enabling the creation of complex shapes without compromising the material’s integrity.

Burr-Free and Stress-Free Parts: The chemical nature of the etching process ensures that the resulting parts are burr-free and have no mechanical stresses or microcracks, which is crucial for components used in sensitive applications such as medical implants, electronics, and precision instruments.

Rapid Prototyping and Short Lead Times: Photo etching facilitates rapid prototyping due to its relatively quick setup process. Design modifications can be easily incorporated without significant additional costs or lead times, making it an ideal method for iterative design improvements and quick turnaround times.

Quick Turnaround Time: The photo etching process typically has shorter lead times than traditional machining methods. Once the design is finalized and the mask is prepared, the etching process can be relatively fast, allowing for quicker production and delivery of parts.

Scalability and Consistency: Whether producing a small batch or scaling up for larger volumes, photo etching maintains consistency in quality and precision across all parts. This scalability ensures that the final product meets the same high standards, regardless of quantity.

Environmental Friendliness: Photo etching is relatively more eco-friendly than traditional manufacturing methods. It produces minimal waste and doesn’t generate harmful by-products, making it a more sustainable choice.

Chemical Resistance and Durability: Etched components often exhibit excellent chemical resistance and durability due to the inherent properties of the base material. This makes them suitable for resilient applications against harsh environments or corrosive substances.

Finally, the photo etching process’s ability to deliver intricate designs with high precision, its material versatility, cost-effectiveness, and environmentally friendly nature make it a preferred choice in industries ranging from electronics and automotive to medical devices and aerospace.